What Does the Journey of a Container through Your Facility Look Like?

You may be familiar with the journey single-use medical waste containers take through a healthcare environment over the course of its lifecycle. But did you know there’s a smarter, more sustainable and user-friendly method for waste management? Daniels is a leader in waste management in Canada and an innovator, providing a new, more intelligent and intuitive way to tackle healthcare waste with our reusable containers that are engineered for greater safety.

To illustrate those differences in experience, we’re going to look at the steps two of our most common products, Daniels Sharpsmart sharps container and Medismart, the first clinically-engineered bagless medical waste disposal container designed to be virtually touchless, take to travel through healthcare settings.

Ready to take an eye-opening look at the journey of these groundbreaking containers? Let’s roll out and see how Daniels reusable, intelligent containers help make healthcare facilities compliant, safe and staff-friendly.

TOPICS WE WILL COVER:

1 / Installed into your facility

3 / Smooth movement throughout the facility

5 / Filled containers easily removed and stored

6 / Safe secure transport beyond the facility

7 / Disposal time and sterilisation

Installed into Your Facility

First, Daniels delivers a healthcare facility’s container in a specially-designed Daniels Transporter to the facility. Since Daniels containers are designed to lock into place easily regardless of the specific container, the transporter can carry them in a secure and efficient manner.

From there, hospital staff can easily move the containers throughout the facility using a bulk delivery cart. Again, because Daniels’ containers are designed to lock into place, they can be quickly loaded onto their specially-made cart, saving staff the need to undertake multiple trips. This helps get containers to the places where they are needed quickly and efficiently.

What makes our carts and containers unique is that all of our S-series containers fit perfectly into these carts, making it easy and convenient to customise your container needs with various sizes. Here, our Sharpsmart and Medismart containers are loaded and ready for placement or storage. They never touch the floor and are fixed in an upright position for their journey throughout the facility.

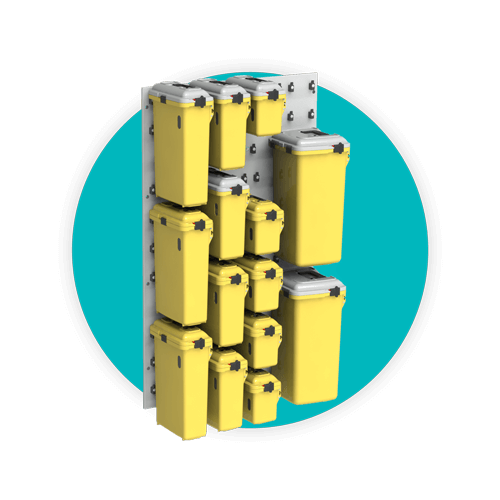

Space-Saving Storage

Many hospitals need to store multiple containers, which can consume much-needed space in utility rooms. That’s where Daniels’ Wallsmart comes to the rescue. Just like Daniels' internal delivery carts are designed to fit multiple sizes, so too are these wall mounting systems, which allow for efficient storage. Here, containers are easy to identify and segregate between empty and full.

Smooth Movement Throughout the Facility

A ward has filled their containers and needs new ones. Nurses, field service techs, or other hospital staff can quickly move multiple containers with ease thanks to our internal delivery cart. But what about if a nurse or tech wants to relocate a container, maybe from one patient area to another? Here’s where Daniels’ Cartsmart comes in handy for bedside use. The Cartsmart is designed to move easily while securely holding each container.

But that’s not the only benefit of the Cartsmart. Attached to the container, the Cartsmart provides other functions, such as a soft close feature that attaches to the lid of the container and a hands-free foot pedal which eliminates the need to touch any part of the container during disposal. The Cartsmart also features a side-mounting bracket so a second container can be added. This can be especially helpful for ease of waste segregation when handling both sharps and standard biomedical waste, to give one example.

Fixed Locations

Sometimes you don’t want your waste containers to be easy to move. That’s why Daniels has a non-mobile solution that allows for secure installation of its waste containers. Let’s say we need to secure containers in patient rooms. Here, wall mounting is an easy solution thanks to fixed mounting brackets and a dovetail design that allows for easy securing with a downward locking mechanism.

Filled Containers Easily Removed and Stored

Let’s move on to what happens when our containers have become full. Record-keeping and analysis are easy thanks to every container coming equipped with a barcode. Here, a service tech can scan this code and instantly identify its placement within the hospital. Then the container is locked using the simple-to-use side-locks, preventing any additional access to the container. From here, it can be easily moved and added back onto the Wallsmart system for storage before disposal or sent right to the delivery dock using the internal delivery cart.

Another feature that makes Daniels’ system unique is its optimised transfer process from cart to Daniels transporter. During this entire process, containers never touch the ground and remain upright and secure. But as you probably know, a healthcare facility's responsibility doesn’t end there. Remaining compliant through the entire cradle-to-grave life cycle of medical waste is essential and part of that is the journey after containers leave the hospital.

Safe and Secure Transport Beyond the Facility

Daniels understands that you’re responsible for the safe transportation of medical waste to its disposal facility. That’s why we created a safer system that eliminates much of the risk involved with medical waste transportation. Containers remained locked through the entire transport process, which helps prevent spills or other accidents. And, just as empty containers arrive fully locked and secured within the transport truck, filled containers also are secured within the vehicle, keeping them locked upright throughout the trip to the disposal centre.

Disposal Time and Sterilisation

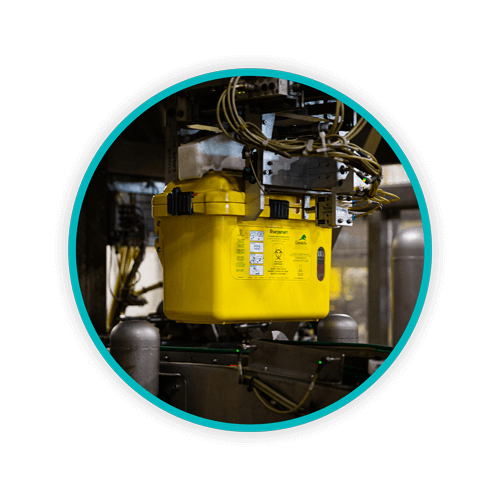

Daniels containers arrive at a Daniels waste processing facility the same way they leave the hospital thanks to their leak-proof seal, locking system, and secure, upright position. Once containers reach our facilities, they are safely unlocked, emptied, and sterilised as part of our robotic washline technology.

After containers are fully emptied, they are given an extreme washing. In this phase, containers are placed in a washing chamber that uses environmentally-friendly cleaning products coupled with intense water jets and steam technology. This provides the most comprehensive bacterial load reduction and has been independently tested to demonstrate a high level of sterilisation that is actually higher than that required by the US CDC.

If the Daniels container journey sounds like an improvement over your current system, reach out to the Daniels team to learn more. We’ve helped many of Canada’s leading health care organisations to create smarter and safer medical waste solutions that are both cost-effective and user-friendly.